Effective Dust Control Fans for Agricultural Facilities: Improve Air Quality & Performance

Ensuring cleanliness in agricultural facilities is crucial for both product integrity and employee safety. These environments manage a variety of ingredients and face numerous risks, demanding effective management strategies.

Managing Dust at Furst-McNess Agricultural Facilities

At Furst-McNess, the ongoing presence of combustible dust is well acknowledged. Their dedication to safety and compliance has guided them toward an automated dust control solution.

According to Ron Kerkhoff, the operations manager at Furst-McNess, implementing SonicAire Fans in the load-out receiving area is projected to save around $10,000 annually in overtime costs. By minimizing the requirement for extensive monthly cleaning, they reduce labor hours while enhancing safety and cleanliness without interrupting daily operations.

Challenges of Fugitive Dust in Agricultural Facilities

Dust is an omnipresent issue in agricultural settings, raising concerns such as:

- Strict Compliance Standards

- High Housekeeping Costs

- Labor-Intensive Cleaning Efforts

- Risks of Combustible Dust Explosions

- Employee Health Risks

- Potential Citations and Fines

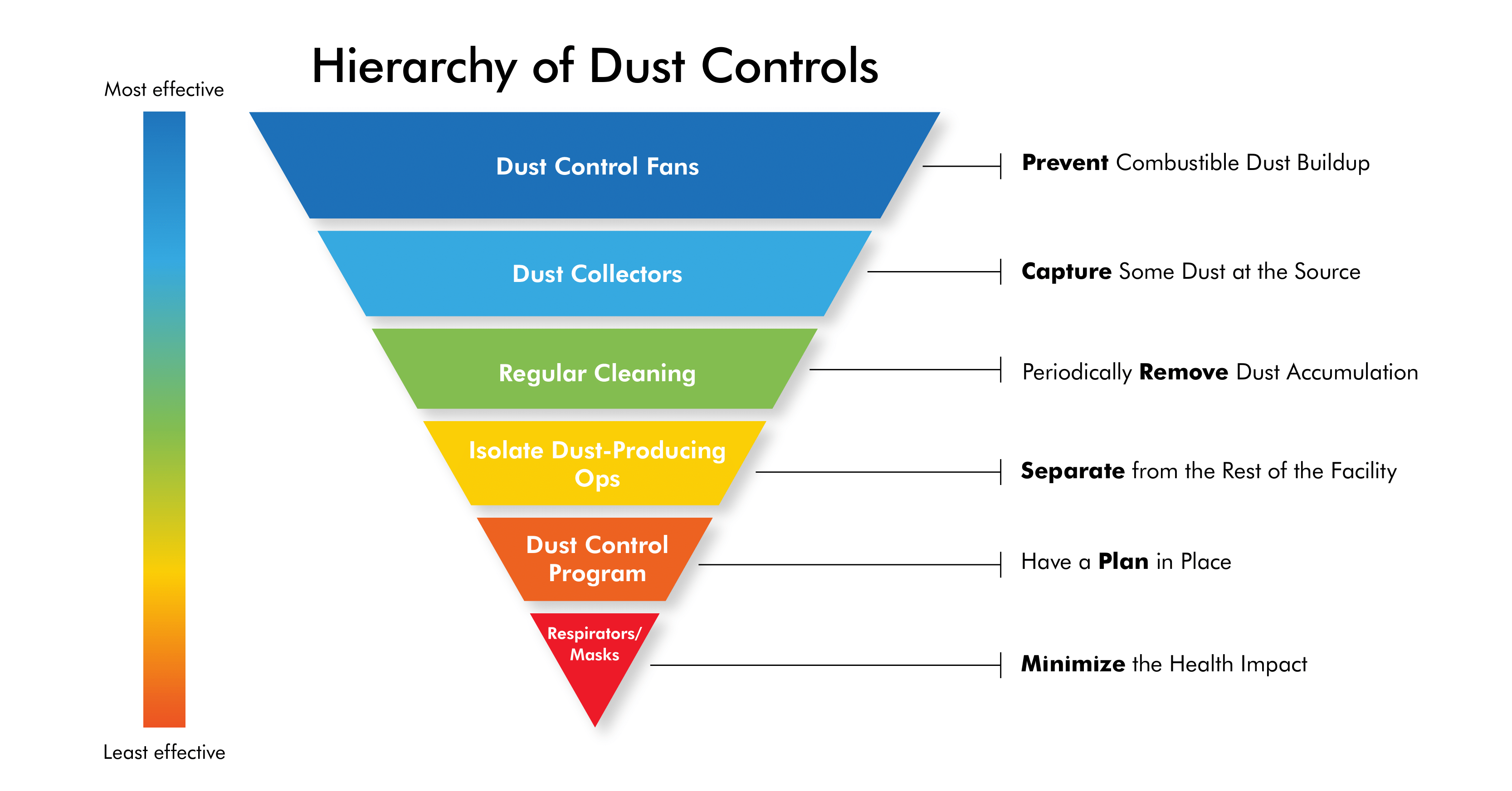

The Dust Control Hierarchy

What is the Most Effective Solution?

Various methods exist for managing dust hazards, each with differing levels of effectiveness. Below is a ranked list based on their efficiency:

- Dust Control Fans [Elimination/Prevention]

These fans generate an airflow barrier that hinders dust from settling in hard-to-reach spaces like ductwork and beams, facilitating its removal and addressing combustible dust risks. - Dust Collectors [Elimination]

Dust collection systems significantly capture dust generated during primary operations. However, they may not completely eliminate fugitive dust, classifying them as a partial solution. - Regular Cleaning [Substitution]

This method involves manual cleaning of dust-prone areas, which, while effective, is labor-intensive, costly, and poses risks to employees, particularly in elevated zones. - Isolating Dust-Producing Operations [Engineering Controls]

This strategy isolates hazardous processes to reduce exposure. While partial isolation is achievable, some dust may escape and present risks to nearby staff. - Dust Control Program [Administrative Controls]

Implementing control programs with inspections and hazard assessments can help manage risks but do not directly affect dust generation and accumulation. - Masks/Respirators [PPE]

Utilizing personal protective equipment reduces inhalation of dust but offers limited protection against the explosive characteristics of combustible dust.

By prioritizing elimination and prevention strategies, agricultural facilities can enhance their dust hazard management, ensuring a safer workplace for employees.

How Do Dust Control Fans Combat Fugitive Dust?

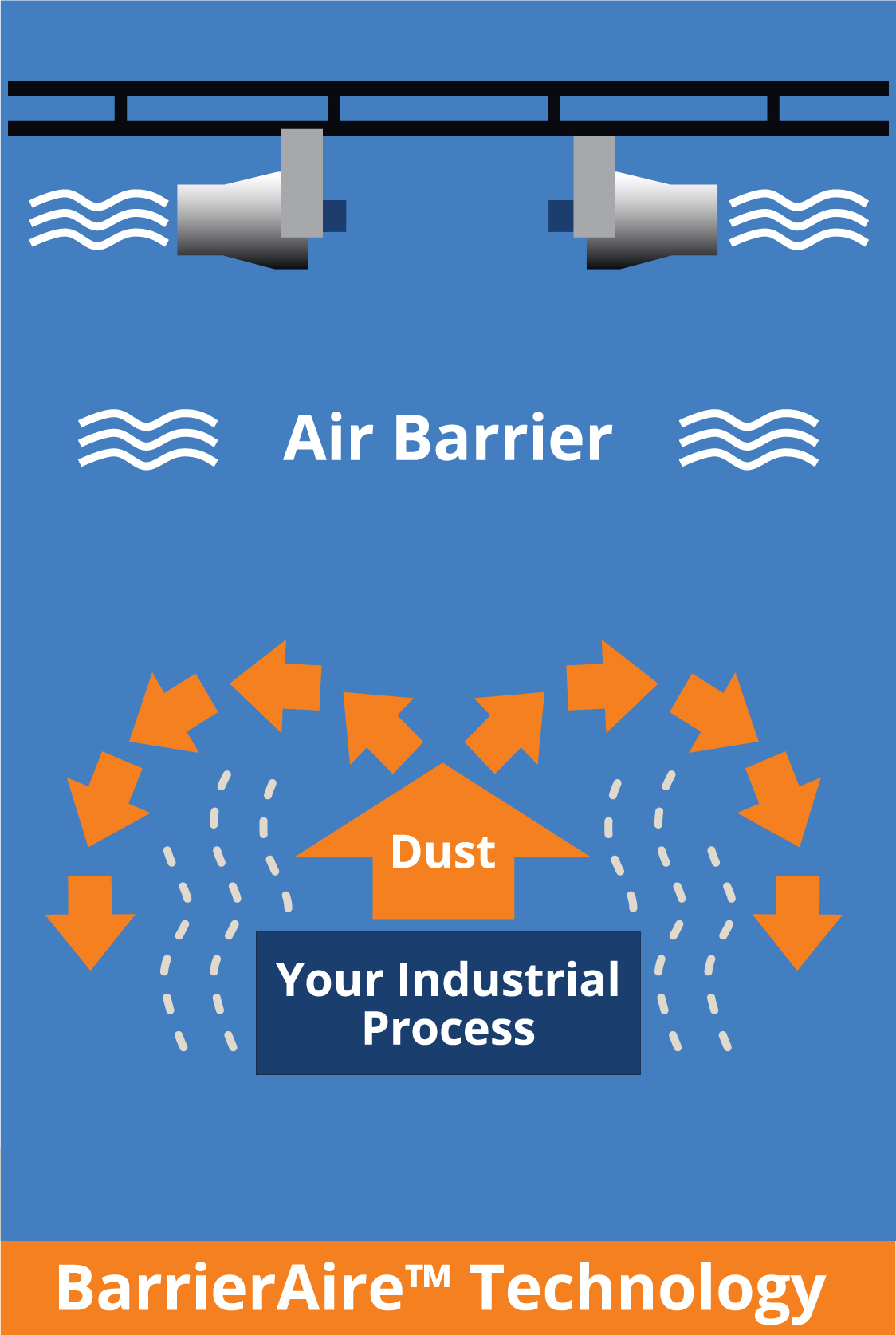

SonicAire’s proprietary BarrierAire technology, specifically designed for agricultural dust control, has the potential to transform dust management within facilities:

High-Velocity Airflow: Create a powerful airflow that prevents combustible agricultural dust from accumulating on overhead structures.

Thermal-Current Control: Regulates thermal currents to stop dust accumulation in difficult-to-access areas that may present fire and explosion hazards.

Automated Dust Management

SonicAire fans, featuring BarrierAire® Technology, streamline dust management, simplifying the process of maintaining cleanliness and safety without extending work hours or interrupting production for cleaning.

Introducing the CIID1-Certified XZ-210 and XZ-215 Fans

The new CIID1-certified XZ-210 and XZ-215 fans are tailored for environments susceptible to hazards and potential explosions, such as agricultural facilities. They are engineered to meet rigorous industry standards, delivering outstanding performance in dust prevention while complying with NFPA and OSHA regulations.

Leveraging BarrierAire™ technology, the XZ-210 and XZ-215 fans effectively disrupt thermal airflow patterns, promoting the aggregation of combustible dust particles to settle on the floor instead of accumulating in hard-to-clean places.

Continuous Cleaning Backed by SonicAire’s Compliance Guarantee

SonicAire is so confident in the efficacy of its products for alleviating fugitive dust challenges that it offers the SonicAire Compliance Guarantee*.

If SonicAire fans, when installed and maintained per their guidance, do not eliminate the need for overhead cleaning, they promise a full refund or reimbursement of any imposed fines, whichever is less.

Maria Sanchez completed her Bachelor’s degree in Plant Sciences from the University of California, Davis, in the USA. Her studies focused on plant genetics and biotechnology, with an emphasis on developing disease-resistant crop varieties. Maria has contributed to several research projects aimed at improving crop resilience to climate change and is now pursuing her Master’s degree in Plant Breeding.